First Ever 20,000 PSI Offshore Chemical Injection System

“Anchor is the industry’s first deepwater high-pressure development to achieve a final investment decision…. With an operating pressure of 20,000 psi, it is one of the first ultra-high-pressure projects in the world.”

Offshore Magazine, Regional Reports, April 1, 2020

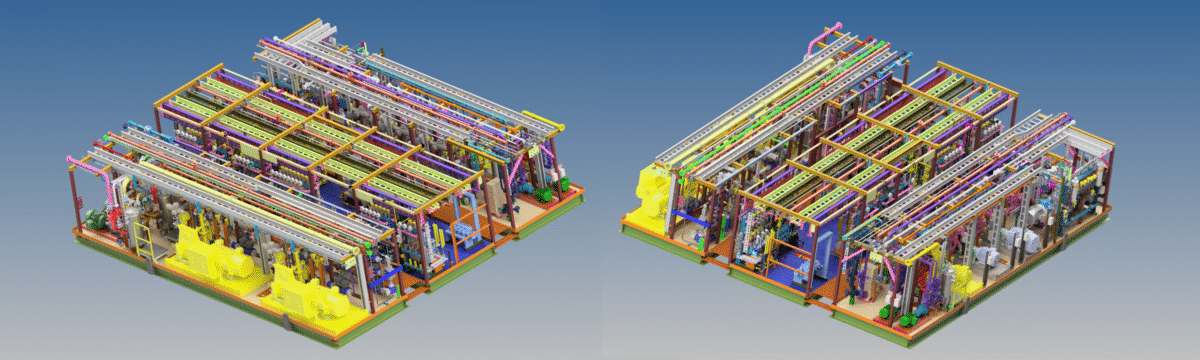

Subsea Methanol Injection

- 2 – Centrifugal Charge Pumps 200 GPM @ 160 psig

- 2 – Vertical Triplex High Pressure Pumps, 25 GPM flowrates and 15,340 PSIG pressure

- Suction side 316 SS welded pipe

- Discharge 3” 2507 SDSS welded pipe

- Flow distribution racks with 20,000 PSIG Flow Meters and Pressure Control Valves

- 10’6” W x 40’ L x 10’ H

- Dry Weight 79,300 LBS

- This skid is the left side of the 3 skid package creating a 40’ x 40’ area of Injection Equipment

Topside Chemical Injection

- 40 – High Pressure Injection Pumps with flow rates 0.23 GPH to 60 GPH and pressures from 135 PSIG to 3,680 PSIG

- All 6mO alloy tubing

- 10’ W x 40’ L x 10’ H

- Dry Weight 41,800 LBS

- This skid is the middle of the 3 skid package creating a 40’ x 40’ area of Injection Equipment

Subsea Chemical Injection

- 2 – Centrifugal Charge Pumps 55 GPM @ 100 psig

- 4 – High Pressure Injection Pumps with flowrates from 1.75 GPH to 8.75 GPH and pressures from 6,200 PSIG to 13,850 PSIG

- 3 – Vertical Triplex High Pressure Pumps with flowrates from 3 GPM to 8 GPM and pressures from 14,030 PSIG to 15,340 PSIG

- Suction side 6mO alloy tubing and 316 SS welded pipe

- Discharges of 2507 SDSS Autoclave tubing and 1.5” 2507 SDSS welded pipe

- Flow distribution racks with 20,000 PSIG Flow Meters and Pressure Control Valves

- 10’ W x 40’ L x 10’ H

- Dry Weight 65,640 LBS

- This skid is the right side of the 3 skid package creating a 40’ x 40’ area of Injection Equipment