With over 100 years of combined experience, AGI delivers comprehensive pump system solutions from initial concept through ongoing maintenance. Our integrated approach combines in-house professional engineering, advanced fabrication capabilities, and specialized testing facilities to provide custom-engineered package solutions for the most demanding applications.

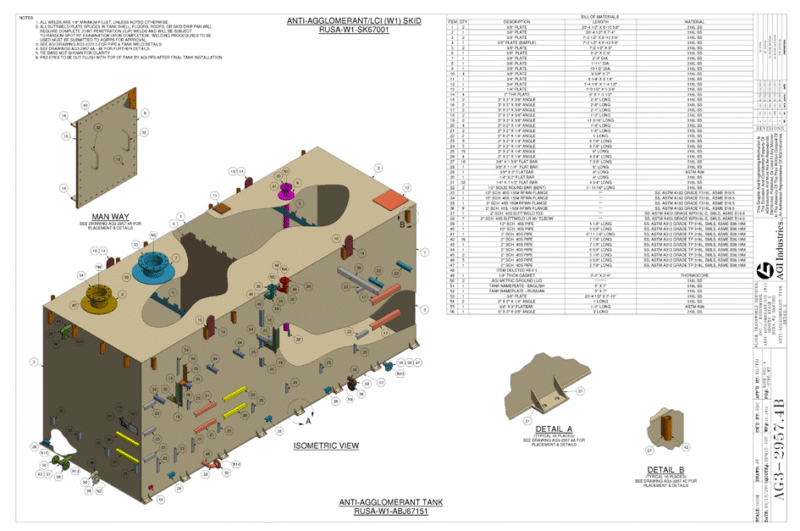

Our team manages every aspect of your project through web-based systems that ensure clear communication and visibility throughout the entire process. From high-pressure systems reaching 15,000 psig (with development for 20,000 psig) to complex custom designs, we leverage cutting-edge engineering software including Autodesk Mechanical Simulation FEA, RISA Technologies, and 3D modeling technology to deliver precise, reliable solutions.

Operating from our extensive facility complex featuring 150,000 sq ft of outdoor fabrication, 20,000 sq ft indoor fabrication facility, 5,000 sq ft enclosed assembly/testing facility, and 2,500 sq ft warehouse, we maintain complete control over quality and timelines. Our specialized testing capabilities include a unique high-capacity test site with a 48″ ID x 30 ft deep stainless steel pit and 120,000-gallon freshwater reservoir system, enabling comprehensive validation testing including 8-hour fully loaded string tests with complete data documentation.

Whether you need estimating and project management, engineering and design, drafting, document control, procurement, fabrication and testing, installation and commissioning, or ongoing maintenance and troubleshooting through our REAcT service, we provide the expertise and infrastructure to handle any pump system challenge. Our commitment to industry standards (AWS D1.1, ASME B31.3, API, ANSI, ABS), advanced welding capabilities, and comprehensive project management ensures your pump system project is delivered on time, within specification, and built to perform.

Estimating & Project Management

- 100+ years of combined pump system experience

- Capable of estimating and managing any package project

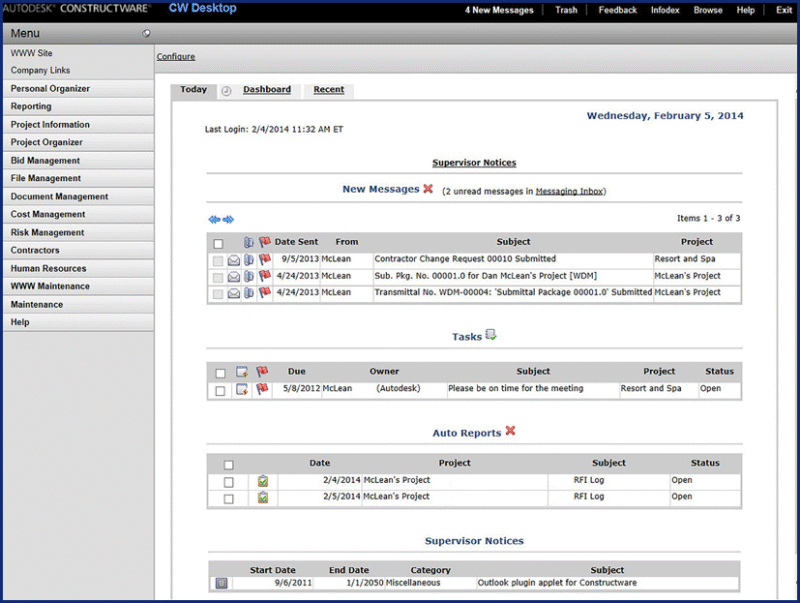

- Web-based project management program provides communication and visibility throughout the pump system project

Engineering & Design

- In-house professional engineering

- Custom engineered package solutions

- High-pressure systems (15,000 psig and development for 20,000 psig.)

- Autodesk Mechanical Simulation Finite Element Analysis (FEA), RISA Technologies Structural Engineering Software, Flow of Fluids Software

- Auto Desk Inventor 3D modeling fabrication drawings

- Client access for in-progress review of design models

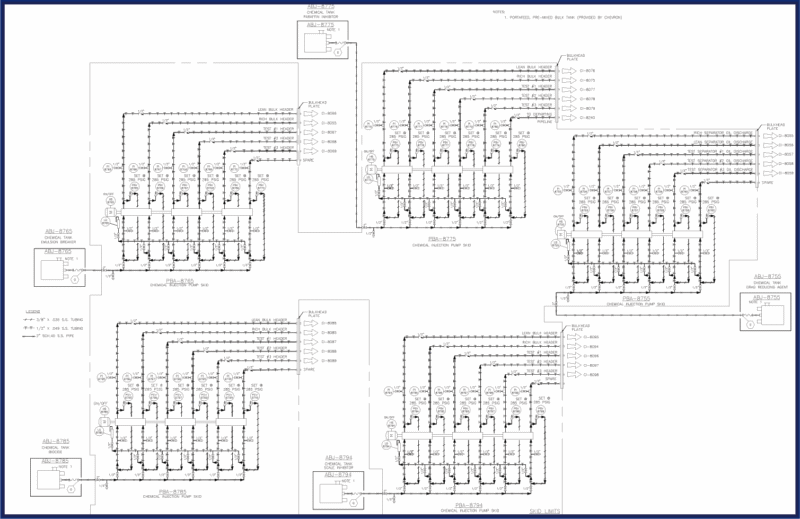

Drafting

- GA Drawings of Pump Systems

- Full Construction Drawings

- 3D Model

- P&ID

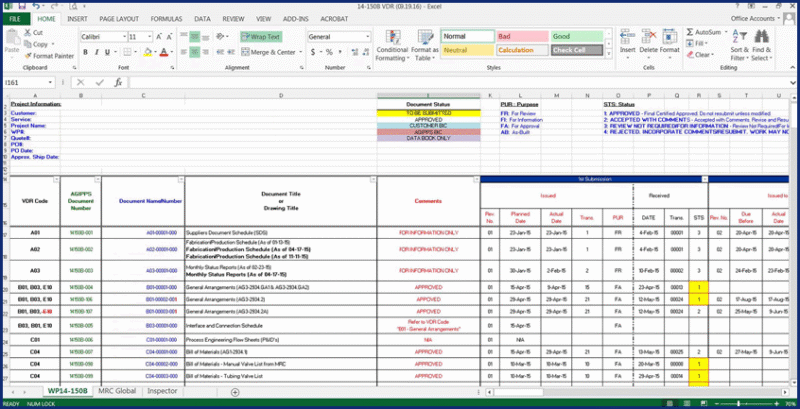

Document & Control

- Retrieval, retention, and distribution of all documents, drawings, correspondence, reports, submittals, RFIs, data books, etc.

- Utilization of various client SharePoint portals for document exchange to receive, expedite, log, file, track, and distribute documentation

Procurement

- Bill of Materials

- Simplified Equipment BOM

- Separate Fabrication & Equipment BOMs

- Procurement Department

- Issues, Expedites, & Executes

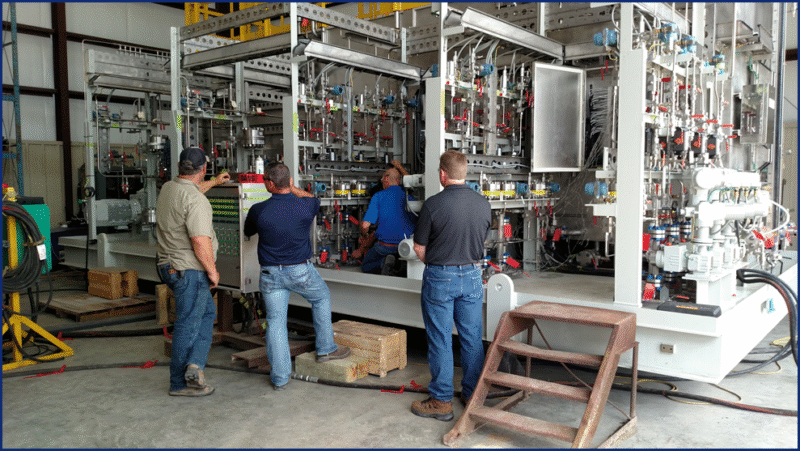

Fabrication & Testing

- Industry Standards (AWS D1.1, ASME B31.3, API, ANSI, ABS, etc.)

- FCAW, GMAW, GTAW, SMAW

- In-house welding: 316SS, Super Duplex, Aluminum, 4130

- Hydrostatic Testing of Pump Systems

- Flushing and Cleaning Capabilities

- Factory Acceptance Testing (FAT) / String Testing

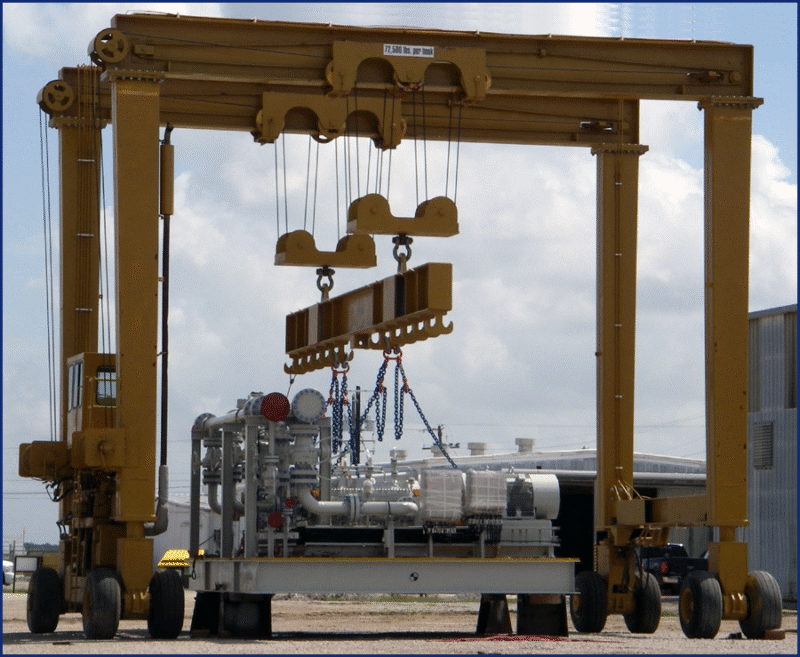

Facility & Equipment

Our Facility

- 150,000 sq. ft. Outdoor Fabrication

- 20,000 sq. ft. Indoor Fabrication Facility

- 5,000 sq. ft. Enclosed Assembly / Testing Facility

- 2,500 sq. ft. Indoor Warehouse

Our Equipment

- Overhead Indoor Cranes

- Forklifts

- Cherry Pickers

- 150,000 lb. Gantry Crane

- Plasma Cutters

- Shielded Metal Arc Welding (SMAW)

- Gas Welding Arc Welding (GMAW)

- Flux Core Arc Welding (FCAW)

- Gas Tungsten Arc Welding (GTAW)

High-Capacity Test Site with Pit

AGI has designed and installed the equipment needed to perform performance and validation testing on large vertical pump and drivers. The equipment includes a stainless-steel test pit that is 48” ID x 30 ft deep. Top of this pit is at grade surrounded by a level concrete slab with imbedded steel runners. The pit is feed from a 120,000-gallon freshwater reservoir (tank) that functions as both a heat-sink as well as allows us to vary the submergence depth (NPSHa) for pump validation. String tests can be performed, including shaft driven pumps with run durations of 8 hours fully loaded being common. Flowrates, temperatures, pressures, etc. are all captured on a laptop for documentation of the testing results.

Services

- Installation of Pump Systems

- Commissioning & Startup

- Repairs & Maintenance

- REAcT

- Trouble shoot, diagnose, & repair nearly any fluid handling or movement related issues.